Decoding the Price of Lace Fabric: A Comprehensive Guide

Lace fabric, known for its intricate patterns and delicate appeal, has been a staple in the fashion industry for centuries. From bridal gowns to lingerie, lace adds a touch of elegance and femininity to any garment. However, understanding the factors that influence the price of lace fabric can be a complex task. In this article, we will explore the various elements that contribute to the pricing of lace fabrics, providing you with insights into the world of lace and its cost considerations.

- Quality of Materials

- Manufacturing Techniques

- Complexity of Design

- Quantity and Scalability

- Brand Reputation

- Market Demand and Trends

1、Quality of Materials:

One of the primary factors influencing the price of lace fabric is the quality of materials used in its production. Higher-quality materials, such as fine silk or premium cotton, tend to be more expensive than synthetic alternatives. The superior strength, texture, and luxurious feel of natural fibers contribute to their higher cost, making lace fabrics crafted from these materials pricier.

As a lover of fine lace embroidery, you may be wondering why some pieces are priced higher than others, even though they may seem similar in design and complexity. The answer lies in a crucial, often overlooked factor – the type of material used. The cost of lace embroidery isn’t solely determined by the intricacy of the design or the labor involved; the material plays a significant role in the price equation.

Embarking on the Lace Journey: A Material Difference

Lace embroidery is a delicate, intricate, and time-consuming process that marries skill and artistry. At the very foundation of this beautiful craft lies the material we use. The choice of material not only influences the look, feel, and durability of the lace but also significantly impacts its price.

To illustrate this, we’ve created a comparison table showcasing the primary materials used in our lace embroidery products – cotton, nylon, polyester, silk, viscose, and metallic wire – and their impact on the cost.

| Material | Complexity of Production | Durability | Aesthetic Quality | Cost Impact |

|---|---|---|---|---|

| Cotton | Low | Moderate | High | Low |

| Nylon | Low | High | Moderate | Low |

| Polyester | Low | High | Low | Low |

| Silk | High | High | High | High |

| Viscose | Moderate | Moderate | High | Moderate |

| Metallic Wire | High | Low | Very High | High |

Each material brings something unique to the table:

- Cotton: With its soft, breathable texture and ease of manufacture, cotton is a popular choice. Despite its relatively moderate durability, its high aesthetic quality and low cost make it an attractive option for many customers.

- Nylon: Nylon is durable and relatively easy to manufacture, translating to lower costs. While its aesthetic quality doesn’t quite match up to natural fibers, its resilience makes it suitable for items subject to regular wear and tear.

- Polyester: Like nylon, polyester is highly durable and easy to produce, making it a cost-effective choice. However, its aesthetic appeal may not be as high as its natural counterparts.

- Silk: Synonymous with luxury, silk offers a high aesthetic quality and remarkable durability. However, its complex production process results in a higher cost.

- Viscose: A semi-synthetic material that mimics the feel and look of silk, viscose offers a good balance of aesthetic quality and durability. However, its manufacturing process is a bit more complex than cotton, polyester, and nylon, which reflects in its price.

- Metallic Wire: Adding a glamorous touch, metallic wire is highly appealing aesthetically. However, it is complex to work with and less durable, resulting in a higher cost.

To understand this better, let’s consider an example. Imagine two identical lace embroidered tablecloths, one made with silk and the other with polyester. Even though the design and workmanship are the same, the silk tablecloth would be more expensive due to the high cost, complex production, and superior aesthetic quality of the silk. In contrast, the polyester tablecloth, though equally durable, would cost less due to the simpler production process and lower aesthetic appeal of polyester.

The same principle applies to all our lace embroidery items, whether they’re home furnishings, clothing, or accessories. The choice of material significantly impacts the final price, accounting for the differences you see in our catalogue.

Understanding the relationship between material and price empowers you to make informed decisions when selecting lace embroidery items. Whether it’s the luxurious sheen of silk, the enduring resilience of nylon and polyester, the soft comfort of cotton, the balanced appeal of viscose, or the striking brilliance of metallic wire, each material

To sum up, when we are accounting for the price of lace, we will weigh the sample lace, calculate the price of raw materials used per yard, plus the loss of raw materials in the production process of lace, the proportion of this loss is almost between 5% and 15%, different processes will be different

2、Manufacturing Techniques

Manufacturing Techniques: The manufacturing techniques employed in creating lace fabric also impact its price. Traditional methods, such as handmade or machine-made lace, require skilled craftsmanship and intricate detailing, resulting in higher production costs. Alternatively, modern technologies like computerized lace machines have made lace production more efficient, reducing costs and subsequently affecting the price.

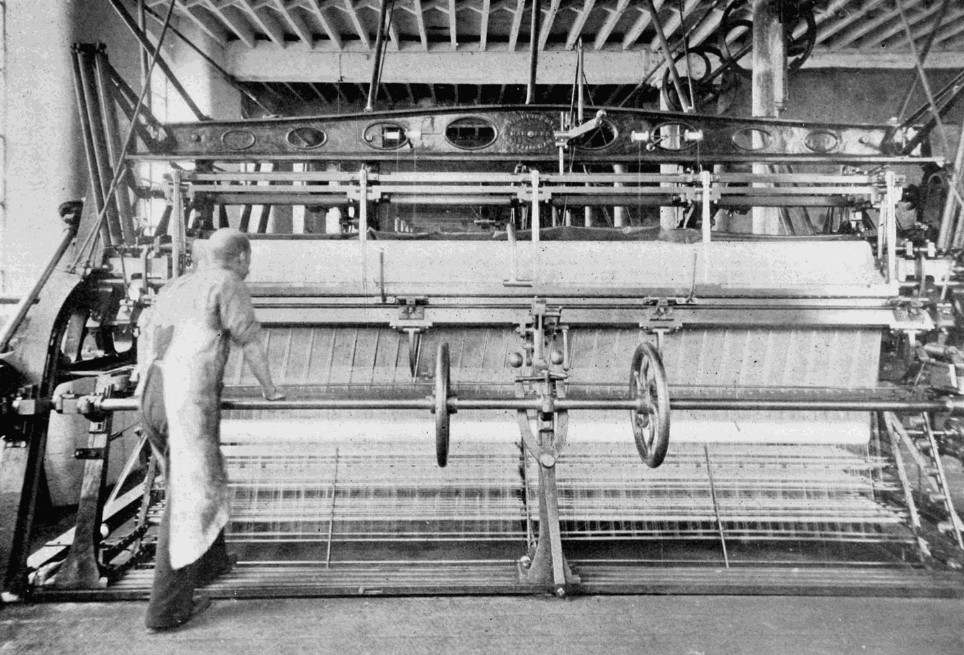

Early lace production

Early lace production

Sure, let’s break down the specific costs of the lace manufacturing process:

- Design Complexity:

- Simple designs: lower labor hours, less machine time, less waste, therefore, lower cost.

- Complex designs: more labor hours, extended machine time, potential for increased waste, therefore, higher cost.

Handmade lace process, flower pattern three-dimensional sense is very strong, flower pattern has softness, aristocratic sense of strong, expensive, a lace skilled craftsmen need more than a month of time

2、Production Technology:

- Standard machinery: relatively lower capital costs, regular maintenance costs, slower production times.

- Advanced machinery: high initial capital cost, higher maintenance costs, quicker production times, better quality assurance.

Early lace production equipment, imitating handmade lace manufacturing process, currently no more than 20 such machines worldwide, the requirements for operators are relatively high, basically the operation of more than 10 years of technical personnel to be able to open up, problems can only be repa

3、Techniques Utilized:

- Standard techniques (simple knitting, dyeing): lower costs in terms of labor skills and equipment.

- Advanced techniques (embroidery, bead stitching, creasing): higher costs due to the need for specialized labor and equipment.

Lace tablecloth

Lace on the shoe

4、Quality Control:

- Minimal quality control: lower labor costs, potential for higher waste and returns, possibly damaging brand reputation.

- Stringent quality control: higher labor costs, less waste and fewer returns, preserves brand reputation.

The inspection of each process of lace is very important, good quality lace is inspected after each step of the production process is completed, so as not to bring the problem to the latter part of the process, which can produce a beautiful lace

5、Production Scale:

- High volume production: lower cost per unit, increased efficiency, but potential for surplus stock.

- Low volume or custom production: higher cost per unit, less efficiency, but typically higher selling price and no surplus.

Lace on fashion

6、Energy Consumption:

- Low-energy production methods: lower running costs, but potentially slower production times.

- High-energy production methods: higher running costs, but potentially quicker production times.

Remember that all these factors interplay in a dynamic balance, depending on the specific operational decisions, market conditions, and strategic goals of the lace manufacturing enterprise.

3、Complexity of Design:

The complexity of the lace design plays a significant role in determining its price. Elaborate and intricate patterns require more time and expertise to produce, increasing the cost. Lace designs with intricate motifs, floral patterns, or delicate embellishments typically command a higher price due to the level of artistry and craftsmanship involved.

As a lace manufacturing expert, I can attest that lace design greatly influences its final price. The concept of design here encompasses not only the lace’s aesthetic qualities but also the technical considerations that dictate its production process. The complexity of the pattern, the techniques used in its creation, the time taken, and the skill required all contribute to its cost, and therefore, its price.

Take for instance a straightforward floral lace design. This design may involve relatively simple patterns with large, open spaces and repetitive elements. It can be easily produced on automated lace-making machinery with minimal manual intervention, thereby reducing labor costs. The speed of production for such designs is also generally faster, which translates to lower manufacturing costs per unit of lace. Thus, simple lace designs often carry a lower price tag.

Now, let’s compare this to a complex Baroque-style lace design. This design is likely to involve highly intricate patterns with dense stitching, and may include intricate elements such as scrolls, leaves, and floral motifs. This complexity requires a high level of precision in production, often requiring more time and advanced machinery or skilled artisanal handwork. It’s also more likely to have a higher rate of production errors, leading to more waste, which adds to the overall cost. Thus, such complex designs are typically priced higher.

The complexity of the design doesn’t only affect the production process but also the pre-production stage, which involves drafting and digitizing the design for machine production. Complex designs require more skilled design work, and this added labor also contributes to the cost.

For example, consider a custom, one-off design for a client. The uniqueness of the design means the development process requires a significant amount of time and effort. From the initial design sketching to the final digitization for machine embroidery, each step is meticulously carried out to capture the client’s vision accurately. This extensive labor and the personalized service add a premium to the final price.

The design can also dictate the techniques and materials used, affecting the cost. A design that incorporates cording, for example, requires additional materials and a different machine setup, thereby increasing the price. A design that calls for hand-beaded elements would need a skilled craftsperson to manually add these details after the lace has been machined, again increasing the cost due to the added labor and materials.

Who says you can’t look chic while chasing dreams? With our lace-trimmed PJs, you’re not just sleeping, you’re making a fashion statement! Think of lace as the moonlight’s secret love letter to your nightwear. So, kick the bland, invite the grand, and with our lace-laced pajamas, even the Sandman will applaud your style!

The impact of the design on the price of the lace becomes evident when we consider factors like color as well. A multicolor design requires a more complicated dyeing process, or multiple thread changes during the machining process, both of which can add to the cost and, subsequently, the price.

To sum up, the design of lace is a fundamental aspect that shapes its price. From the complexity of the design to the techniques used in bringing it to life, each aspect of the design has a cost implication. As buyers, understanding these aspects can help appreciate the value and workmanship that goes into each piece of lace. As manufacturers, being aware of these factors can help in effectively managing production costs and setting a fair and competitive price.

4、Quantity and Scalability

This is a fine metal wire woven lace, metal wire three-dimensional sense of good, hard feel, but poor toughness, so the machine can not be too fast when the machine is opened, or it is easy to break the line, so his price is much more expensive than ordinary lace

In the intricate and ornate world of lace production, price determination is a nuanced affair. While several factors influence this delicate calculus, the volume of orders is particularly pivotal. Understanding this correlation is key for both buyers and manufacturers in planning production and sales strategies. This article aims to untangle this relationship and explain the significance of order volume on the pricing of lace.

Scale Economics

The economies of scale principle suggests that as the quantity of production increases, the cost per unit decreases. This is due to fixed costs like machinery, rent, and utilities which are spread out over a larger number of units as production grows. For lace manufacturers, larger orders allow for continuous and efficient use of resources, thus driving down per-unit costs.

However, the intricacies of lace production bring additional considerations. Lace creation, especially high-end, customized designs, often involves significant craftsmanship, time, and intricate work. This means that even with higher order volumes, the potential for cost reduction might not be as drastic as in other mass-produced goods.

Customization vs. Standardization

The degree of customization also significantly influences the price dynamics. For standard designs chosen from existing patterns, higher order volumes could lead to greater price flexibility due to reduced design and setup costs. In contrast, each piece of customized lace involves unique design and setup costs, which might not decrease substantially even with higher volumes.

Material Costs and Supply Chain Dynamics

In lace production, the cost of raw materials like cotton, silk, or synthetic threads can constitute a substantial portion of the total cost. Bulk purchasing of these materials could result in cost savings, which could be passed onto the customers through lower prices. However, this is subject to global supply chain dynamics and commodity prices, which could fluctuate due to various economic or geopolitical factors.

Quality Maintenance and Production Capacity

While larger order volumes can drive down per-unit prices, manufacturers must ensure that the quality of lace isn’t compromised in the process. Furthermore, increasing production beyond a certain limit might require additional investment in machinery or labor, which could potentially offset the cost advantages gained from higher order volumes. Hence, there is an optimal level of production where cost efficiency and quality can be maximized.

Demand and Market Conditions

Market demand and competition can also influence the relationship between order volume and lace pricing. In periods of high demand or limited competition, manufacturers might not be as willing to offer significant price reductions for higher order volumes. Conversely, during periods of lower demand or heightened competition, manufacturers might use price reductions as a strategy to attract larger orders.

Conclusion

In conclusion, while the volume of orders has a significant impact on the pricing of lace, this relationship is influenced by several factors, including economies of scale, the degree of customization, material costs, quality maintenance, and market conditions. Understanding these dynamics can help both manufacturers and buyers in decision-making and negotiations, ultimately contributing to a more efficient and competitive lace industry.

As always, individual manufacturers, such as Lace Dog, may have their unique pricing strategies and factors influencing their cost structure. Hence, it’s advisable to engage in thorough discussions and consultations to understand the potential price implications of your lace orders. This will help in planning your production schedules, costs, and pricing strategies effectively.

5、Brand Reputation

Brand lace is distinguished by superior quality, unique design, and meticulous craftsmanship. Notably, branded companies like Lace Dog offer customization and uphold sustainability. In contrast, ordinary lace is mass-produced and less personalized, offering affordability but potentially lacking the uniqueness and premium materials of brand lace.

In the ever-evolving world of fashion and decor, lace holds a place of timeless charm and grace. Yet, not all lace is created equal. When comparing brand lace to ordinary lace, the difference in cost often raises eyebrows. This disparity, however, is justified once we delve deeper into the intrinsic value and unique aspects of brand lace.

Branded lace, like those meticulously crafted by Lace Dog, is an epitome of elegance, finesse, and exclusivity. It’s an outcome of careful selection of materials, precise manufacturing processes, and the unceasing pursuit of perfection. Such commitment and attention to detail set brand lace apart from its ordinary counterparts.

Intrinsic Quality and Sustainability

Brand lace guarantees superior quality. The materials used are of the highest standard, offering durability and enhanced aesthetics. Sustainability, a value often overlooked in the realm of mass-produced, ordinary lace, is integral to many branded lace manufacturers. Using environmentally-friendly materials and processes, these brands conscientiously reduce their carbon footprint. Thus, with brand lace, consumers invest in a product that is not only premium in its feel and look but also ethically produced.

Artistry and Craftsmanship

The price of brand lace also factors in the extraordinary artistry and craftsmanship involved in its production. These pieces are products of countless hours of diligent work by seasoned artisans, who weave their creativity and passion into each design. Every piece of brand lace tells a story, carrying the energy and heart of the artisan who crafted it. This level of individual attention and artistic input is something that ordinary, mass-produced lace lacks.

Design and Customization

One of the distinctive aspects of brand lace is its unique design. Companies like Lace Dog offer an astonishing variety of designs – over 50,000 patterns, each different, each special. These designs are not just prints; they are pieces of art that add value to the final product they embellish, be it clothing, home decor, or accessories.

Moreover, brands often provide bespoke services, tailoring lace designs to fit the specific needs and preferences of customers. This level of customization is not usually available with ordinary lace, making brand lace a more appealing choice for those who seek originality and exclusivity.

Long-term Value

Despite the higher upfront cost, brand lace presents better long-term value. Thanks to the high-quality materials and expert crafting, brand lace tends to be more durable and retains its charm for longer. Thus, the cost spread over its lifetime often proves brand lace to be a more economical choice.

Conclusion

In conclusion, the uniqueness and superior quality of brand lace more than justify its higher price compared to ordinary lace. It’s an investment in art, craftsmanship, and sustainability – an enduring piece of beauty that brings joy to your life and contributes to a more ethical fashion industry. When you choose brand lace, you’re choosing a product that carries a rich heritage, a unique story, and an unmatchable charm – truly, a class apart.

6、Market Demand and Trends

The pricing of any commodity, including lace, is not immune to the influences of market demand and prevalent trends. Lace, renowned for its intricate detailing and timeless appeal, has a vast array of applications from the fashion industry to home decor. Understanding how the shifting sands of market demand and trends impact its pricing is a crucial aspect of navigating this intricate industry.

Market Demand and Lace Pricing

Market demand, in simple terms, refers to the total quantity of a particular good or service that consumers are willing and able to purchase. For lace, this demand can fluctuate due to various factors, such as changes in fashion trends, seasons, and economic conditions. As demand for lace increases, its price tends to rise due to the heightened competition among buyers for the limited supply. Conversely, if the demand for lace decreases, its price is likely to fall as suppliers strive to sell their excess stock.

However, the impact of demand on lace prices is also influenced by the elasticity of supply, which refers to the responsiveness of manufacturers to changes in price. For example, if suppliers can quickly ramp up lace production in response to an increase in demand, the impact on price might be less pronounced. On the other hand, if the supply is inelastic, perhaps due to the time-intensive nature of high-quality lace production, a surge in demand might result in a significant price increase.

Trends and Their Impact on Lace Pricing

The lace industry, particularly the high-end sector, is also greatly influenced by fashion trends. For instance, if the fashion industry embraces a lace-centric trend, demand for lace could spike, leading to an increase in prices. This dynamic was evident during the boho-chic trend resurgence, where lace was a key element in many designs, prompting a surge in demand and subsequently, prices.

Similarly, as sustainable and ethical consumption becomes a significant trend in the fashion industry, consumers may be willing to pay a premium for lace products that are produced sustainably. This trend could potentially push up prices for environmentally-friendly lace.

On the flip side, a decline in lace-focused fashion trends or a shift towards simpler, less ornate styles could decrease demand and exert downward pressure on prices.

Trends in Technology and Its Impact on Lace Pricing

Technological advancements also significantly influence the lace industry. Innovations in manufacturing technologies can enhance the efficiency of lace production, leading to lower costs and potentially lower prices. However, as unique and intricate lace designs often require skilled artisans and traditional techniques, the extent to which technology can reduce costs may be limited.

Moreover, trends towards customization and personalization in the fashion industry could impact lace prices. If consumers demand highly customized lace patterns, the additional design and production costs could drive up prices.

Conclusion

In summary, the impact of market demand and trends on lace pricing is multifaceted. Changes in consumer preferences, fashion trends, technological advancements, and broader economic conditions can all influence demand for lace and, consequently, its price. A deep understanding of these dynamics can help industry participants, from manufacturers to retailers and consumers, make informed decisions and successfully navigate the complexities of the lace industry. Ultimately, the timeless allure of lace ensures its continued relevance, irrespective of changing trends and market dynamics.

Conclusion:

The price of lace fabric is influenced by multiple factors, including the quality of materials, manufacturing techniques, complexity of design, quantity and scalability, brand reputation, and market demand. By considering these factors, buyers can make informed decisions and understand the value associated with lace fabrics of varying prices. Whether for a special occasion or a fashionable ensemble, lace fabric continues to captivate with its timeless beauty and versatility.